Collaborative Robotics for Industrial Coating Cells

01/10/2018 – 30/06/2019

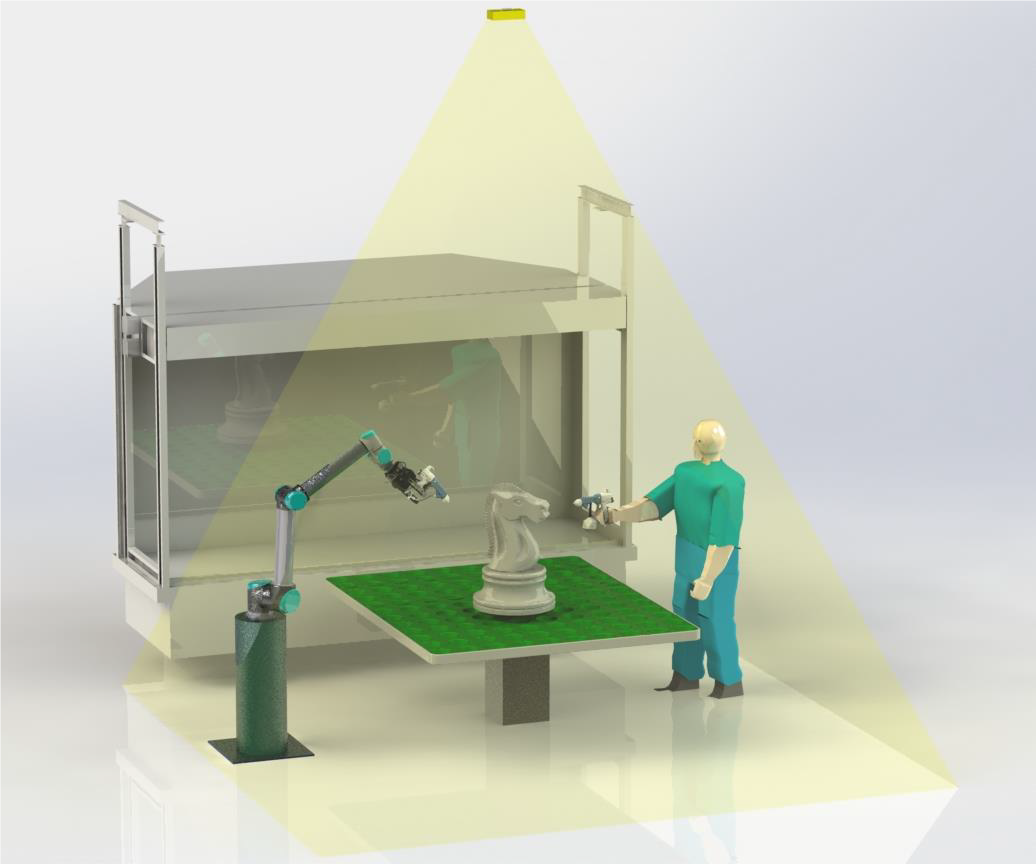

The aim of FlexCoating, an experiment within the HORSE project, is the incorporation of safety features in an existing industrial robotic cell, dedicated to advanced coating application, leading to an enhancement in the cooperation between highly skilled operators and industrial robots, in an especially meticulous operation, conducted on highly customized products of large dimensions and complex geometry.

The experiment will be conducted at FLUPOL, a Portuguese SME specialized in the domain of industrial coating. The company’s main activity is the spraying of complex and delicate products, a highly scrupulous process that, due to the accuracy and reliability requirements, can only be performed manually, by high-skilled operators with more than 8 years training, or by robots programmed by demonstration, due to the finesse and complexity of the manoeuvres required by the process.

In order to remain competitive in a global perspective, FLUPOL specialized in providing a highly customizable service, adapting its production model to satisfy customers’ requirements and specifications. The introduction of industrial manipulators, capable of mimicking with accuracy the manoeuvres from high-skilled technicians, was proven to be a major contribution to FLUPOL productivity and competitive edge in the last years, since they played an important role in contributing to the overall efficiency of the process. However, some challenges are still open-ended problems. One of the main limitations of the current solution is the difficulty to teach coating operations on objects with large dimensions and/or complex geometries.

Therefore, the FlexCoating experiment will tackle these limitations and, consequently, increase the efficiency of the coating process of large and complex components, allowing the company to remain competitive. The experiment will take place in one of FLUPOL’s coating cells, with real technicians, and in a real operational scenario. The coating cell will be adapted to accommodate the industrial sensor that will provide the necessary safety measures to allow an effective collaboration between humans and robots.

Contact: Rafael Arrais ![]()